Around half of Australia's lamb slaughter will be measured by DEXA carcase scanning systems by the middle of next year.

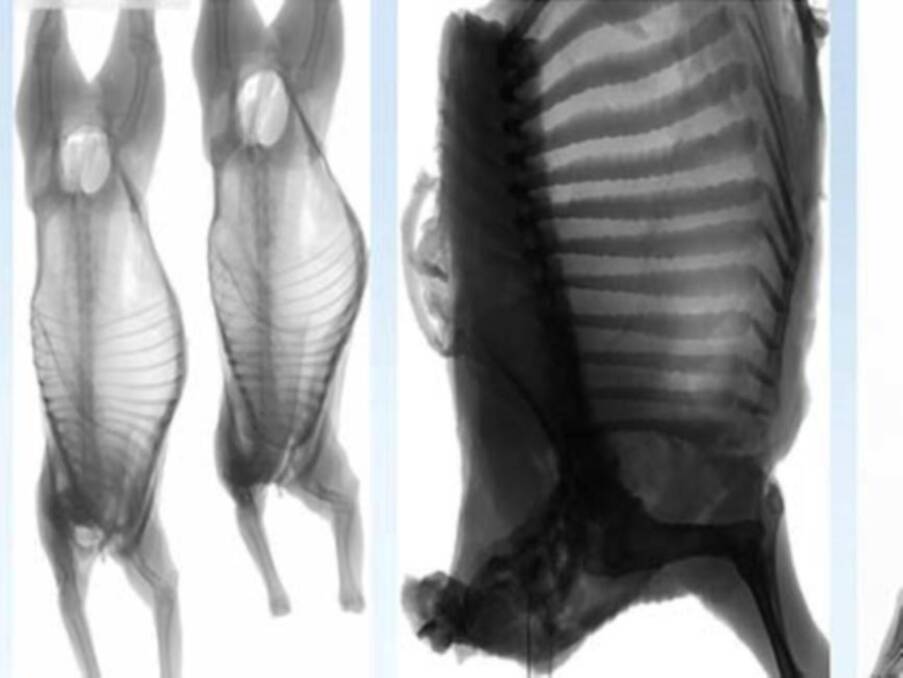

DEXA (dual-energy X-ray absorptiometry) technology accurately measures the lean meat yield of a carcase and is one of the key planks in building the industry's holy grail, a value-based pricing system for the lamb processing chain.

DEXA systems are already installed at JBS Brooklyn, Victoria, JBS Bordertown, South Australia, and Gundagai Meat Processors (GMP), Gundagai, NSW.

Graham Gardner, who is leading a nation-wide research project driving the development of commercial carcase measuring and eating quality technologies, said three more DEXA units would be installed by WAMMCO, Western Australia, the Frew Group, Stawell, Vic, along with another Victorian plant.

The Murdoch University-based academic and livestock scientist is program leader of ALMTech (Advanced Livestock Measurement Technologies) which is managing the project on behalf of Meat and Livestock Australia and a host of partners including universities, departments of agriculture, beef and lamb processors, big supermarkets and livestock organisations.

The project scored $5.4 million earlier this year under the federal Rural R&D for Profit grants plus three times more in cash contributions and in-kind support from its research partners for its work over the next three years.

Dr Gardner said the focus would be on supporting the successful technologies right through to full commercialisation.

"It's one thing to develop these research prototypes, it's always the next challenge to translate them into commercial use in the real world," he said.

The DEXA units at JBS Brooklyn and JBS Bordertown are "cold" systems with the scanning done on chilled carcases.

The images not only calculate lean meat yield (the bone, muscle and fat content) but also steer robots to cut up the carcase into hind and fore quarters and middles which another robotic machine cuts into racks and loins.

Gundagai has installed a "hot" DEXA system which takes scans on the slaughter floor. This aids the quicker sorting of carcases into potential market segments and provides quicker feedback to producers.

But the "hot" system doesn't yet allow robotic cutting up of the carcase, Dr Gardner said.

"Farmers want to know the lean meat yield of their carcase - they are keen to get that feedback," Dr Gardner said.

The data allows for improved sheep breeding values for lean meat yield while processors can more accurately predict the weight of cuts.

The other major strand of ALMTech's work is finding and testing technologies to predict eating quality.

Dr Gardner said companies were coming to ALMTech with their technologies for testing and evaluation.

Imaging technologies such as hyperspectral cameras which operate on a cut surface were showing promise in predicting key eating-quality traits like intramuscular fat (marbling) and meat colour.

"We are checking out a whole bunch of cameras," Dr Gardner said.

Other technologies that don't need a cut surface to measure eating quality traits including probes are also being investigated.

Dr Gardner said the successful introduction of technologies to measure lean meat yield and eating quality would also hinge on the development of an accepted trading language to put a value on the desired traits right along the supply chain.

But that was an issue for the commercial industry to decide, not researchers, he said.

Victorian lamb producer and director of Sheep Producers Australia, Michael Craig, said value-based marketing would send clear price signals back to producers on what consumers wanted.

He said price now was largely determined by how many sheep turned up at the saleyards on any given day.

"The signals we producers are getting aren't about quality, they are about supply. For our consumers, is that the smartest way to do it? I don't think so," Mr Craig said.

"The best way we can do that is price incentive, (and) the best way to get price incentive is to link it back to what the consumer and the processor need, pay on yield and eating quality."

Mr Craig said accurate objective measurements for meat yield and eating quality could be used to underpin more premium lamb brands.

"DEXA will only measure (lean meat) yield," he said

"There's a massive risk if we just focus on yield as a price point then we will forget about IMF (intramuscular fat); we'll forget eating quality.

"The future is measuring yield, measuring eating quality and getting paid for it,

Mr Craig said current booming lamb and mutton prices would take away pressure for change away from traditional saleyard selling.

"But it doesn't mean that industry shouldn't be thinking about the long term.

"What value does a saleyard add to a product? It stresses the animal, how does that improve eating quality. Saleyards are not measuring liveweight, meat yield and eating quality."

He said the industry's main price guide, the Eastern States Trade Lamb Indicator (ETLI), was based on reported saleyard prices.

Saleyards averaged animals on guesstimates of liveweight, fat cover and dressing percentage and was part of a production, rather than consumer-driven, chain, he said.

Should an averaging system be the mechanism to set the price for the finished animal, he asked.

Saleyards also involved costs including transport charges along with agents' and yard fees.

Mr Craig sells all the prime lambs - around 7000 lambs and 4000 mutton sheep a year - produced on his family's farm business near Harrow in Victoria's Western District, direct to a processor.

He said one of the hurdles standing in the way of more direct sales to processors was an historic mistrust between them and many farmers.

The successful introduction of a commercial objective carcase measurement and payment system would help rebuild confidence and trust.

One part of the supply chain couldn't have an advantage over another part.

"I'd be surprised in 20 years time if we are still wedded to saleyards," he said.

.